This has been discussed many times, here and elsewhere on the interwebs. But no one besides Mr. Pettifogger, has actually shown how they do it. So I decided today, that since I was going to be fixing this 1860 Army's short arbor anyway, that I may as well document it and show what I do.

Now let me get this disclaimer out of the way first. There are several ways of doing this procedure. Some epoxy the shim in the hole. Some epoxy a brass shim to the arbor. I don't do it either of those ways, and I'll tell you

MY reasons why.

First, I have an aversion to using glue (epoxy) on a gun. It's just me. If you like JB Weld or whatever other glue you use, that's A-OK with me. It's your gun, do as you see fit. No need to argue about it here.

Second, I don't like to permanently attach the shim down in the arbor hole on the barrel. What if it needs to be removed for some reason? Maybe you need to sell your gun, and the would be new owner doesn't want it modified, for any reason. You're stuck. Because you ain't gettin that JB Welded shim outta that hole! Not without possible damage to the gun.

I like my method because it doesn't permanently alter the gun. It's 100% reversible, and it doesn't harm the gun. There, that's outta the way. So here we go!

First thing I do, is disassemble the gun. Pull the wedge and remove the barrel and cylinder. Now clean all the oil off the arbor and down in the arbor hole on the barrel assembly. Set them aside.

All you need to accomplish this modification is, a piece of round stock, the same or nearly the same diameter as the arbor. You can get it at a lot of hardware stores, or metal supply houses. I get mine from an odd place. I have an old rammer plunger off a gun I cut the barrel down on. The plunger is no longer needed, so I use it to slice pieces off to fix short arbors. It's steel and it works just fine. I hate to waste stuff!

So now you need a slice of the steel round stock, to use as a shim. You can cut it however you like, I just do it this way so it comes out square and flat. I use a clamp that is designed to hold round stock for drilling. It's just a block with a "V" in it to support the metal, and a clamp to hold it in place. It looks like this with the round stock clamped in.

Once the metal is clamped in, as long as you keep your saw blade flat against the clamp, the shim will be flat and square.

So how do I know how thick of a shim I need? I don't really. I just cut a piece off around .008" and test fit it. Just take your newly cut shim, place it down the arbor hole in the barrel, and reassemble the gun. You'll be able to tell right away it it's too thick or thin. If it's too thick, you can cut another one a little thinner, or use a file and thin it out. If it's too thin, you'll obviously have to cut another one that's thicker.

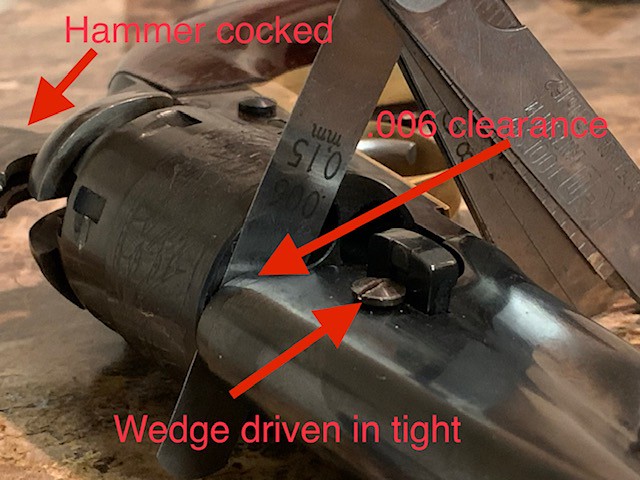

When you assemble the gun for test fitting, put a feeler gauge in the barrel to cylinder gap. See how big it is. The feeler gauges are just automotive type, available at any auto parts store for cheap. Here's how I do mine.

I'm shooting for a cylinder/barrel clearance of about .006"

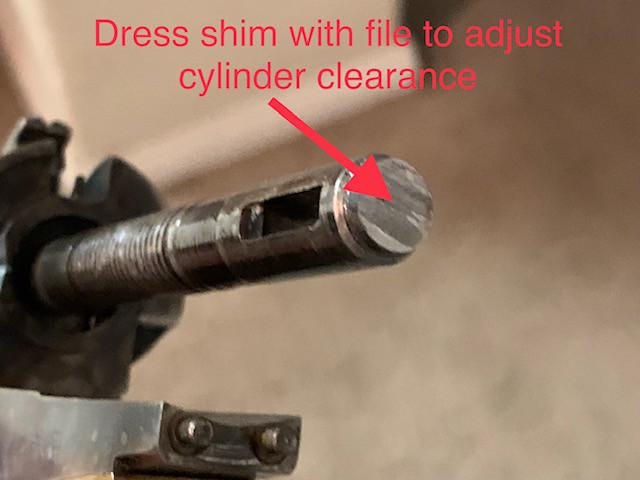

Once I'm in the ballpark, I get ready to solder the shim to the end of the arbor. I start by dressing the end of the arbor with a file. Some arbors have a little "teat" sticking up in the center. You need to remove that so the shim will sit flat. You also need to prep the metal for the solder to grab onto.

Once you've done that, it's time to solder. First I warm the arbor up with a torch. Just warm it up. If you get it glowing red, you got it WAY too hot! Just warm it up.

Next, I put a little dab of paste flux on the end of the warm arbor.

Then I cut a little piece of solder off the roll, and set it on the end of the arbor in the flux.

Now I have to get a little creative. I need a way to place and hold the shim, on top of the arbor so I can heat it and have it stay in the proper position. What I do is, I use the handle off one of my old Exacto knives. It does transfer the heat a little, so wear a glove if you think you might burn your fingers. I don't, because the solder melts so fast that the handle barely gets warm.

I just put a little dab of paste flux on the end of the Exacto handle. it acts as a kind of glue. Then I place the shim on top of that, and another dab of flux on the shim.

Now just turn it up on end, and place the shim on the end of the arbor, covering the solder, and hold it there while you heat the shim up with your torch.

It only takes a few seconds for the solder to melt. Just remove the heat and let it cool a few seconds. You'll know it worked when you see the shim settle down onto the arbor, and you'll see a thin layer of solder around the edge of the shim.

That's it!! It's on there and it ain't going anywhere! Now take the gun in the house, and run some warm water on the end of the arbor to rinse the flux off. Flux is acid, and unless you want your gun to rust in short order, clean it off! Then dry it and oil it up good.

Once you have the gun cleaned and oiled, you'll want to reassemble it again. Once it's back together, check the cylinder/barrel clearance again with the feeler gauges. If it's where you want it, You're done! Go shoot the thing! If it's too loose, which it may be now, because the solder will add a small amount to the end of the arbor, just dress the shim with a file and re-check the fit.

Now, you can set the cylinder/barrel clearance to whatever you like. Some guys like it a bit on the bigger side, to account for fouling. Some like a bit smaller. I've seen anywhere from .003 to .006 being touted as optimal. If I get mine to around .005 I'm a happy camper.

Here she is, all back together and ready for action!

Hopefully I didn't bore you with all the pictures and descriptions. I just wanted to be as thorough as I could be, to hopefully help someone. It took me longer to put this post together than it took me to fix the gun. It really isn't hard, just about anyone can do it. I hope it encourages some to give it a try.